PLEASE NOTE: Effective 2019, we no longer supply Control Techniques variable frequency drives and components. We have drives from several other manufacturers which can meet or exceed the performance characteristics of the Control Techniques line. Simply complete the form below, or contact us with the model of your current or obsolete Control Techniques drive and we’ll be glad to identify a suitable replacement.

Also, the Fincor and Saftronics lines of AC variable frequency drives, DC variable speed drives, and reduced voltage starters were once owned by Emerson but have been obsolete for several years. However, we have many years’ experience working with these drives and can quickly identify replacements capable of exceeding the quality and performance of these older drive technologies. For a suitable replacement, fill out the form below or contact us with your drive or application requirements, and we’ll handle it from there!

|  |

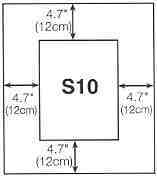

(Obsolete) Saftronics S10 AC Drives

(Obsolete FINCOR Series 5740)

- Saftronics S10 AC Drives – Part Numbers, Pricing, Dimensions & Weights

- Options & Accessories

- Standard Specifications

- Dimension Sheets

- Basic Wiring Diagram

Standard Specifications

| Environmental Conditions | |

|

|

|

| Enclosure | IP20- Protected Chassis; IP65 – NEMA 4X (Indoor Duty) |

|

|

|

| Installation Location IP20 | Do not install in locations where product could be exposed to dust, corrosive gas, inflammable gas, oil mist, vapor, water drops or direct sunlight. There must be no salt in the atmosphere. Condensation must not be caused by sudden changes in temperature. For use at altitudes of 3300 ft. (1000m) or less without derating. |

|

IP65 / NEMA 4X |

Intended for use indoors to protect the enclosed equipment against splashing water, seepage of water, falling or hose directed water and severe external condensation. Installation should be less than 1000 meters (3300 feet) elevation, not in contact with corrosive gas, oil mist or direct sunlight. |

|

|

|

| Ambient Temperature | -10°C to +50°C (+ 14°F to 122°F) |

|

|

|

| Ambient Humidity | 0 to 95% RH (non-condensing |

|

|

|

| Vibration | under 1 G (9.8 m/s2) |

|

|

|

| Storage Temperature | -25°C to +65°C (-13°F to 149°F) |

|

|

|

| Cooling Method | 0.25 to 1 Hp – Convection 2 Hp and greater – forced air (integral fan) |

|

|

|

| Input Frequency | |

|

|

|

| Power System | 115VAC / 200-230VAC / 460VAC single or 3-phase, +10% to -15% V, 50-60 Hz +5% to -5% Hz |

|

|

|

| Output Frequency | |

|

|

|

| Setting | Maximum frequency: 0 to 200 Hz (in 1 Hz steps) |

|

|

|

| Accuracy (Stability) | Digital setting: +0.1 % of maximum frequency (from -10°C to +50°C) Analog setting: +1.0% of maximum frequency (at 25°C +1O°C) |

|

|

|

| Setting Resolution | Digital setting: 0.1 Hz (99.9 Hz or less), 1 Hz (100 Hz or more) Analog setting: 0.06 Hz / 60 Hz |

|

|

|

| Control | |

|

|

|

| Control Method | Sinusoidal PWM V/Hz control |

|

|

|

| Operation Method | Keypad operation: RUN or STOP key Input signal: Forward/Reverse command, Command-to-stop command, Trip command (external alarm and alarm reset) |

|

|

|

| Frequency Setting | Keypad operation: INC (UP) or DEC (DOWN) keys Built-in or external potentiometer of 1 to 5 k ohm (NEMA 4 only) Analog input: 0 to 10 VDC / 4 to 20 mA DC / 0 to 20 mA DC Multistep frequency: Up to 2 different frequencies can be selected using [OXO] input terminals |

|

|

|

| Indication | Running: Digital indication of output frequency or output current (3-digit LED) Tripped: Cause of trip by code (3-digit LED) |

|

|

|

| Acceleration/Deceleration Time | 0.1 to 999 sec. (independently adjustable acceleration and deceleration) |

|

|

|

| Voltage/Frequency (V /F) Characteristics |

6 selectable V /F patterns |

|

|

|

| Restart After Momentary Power Failure | Drive restarts without causing the motor to stop when the automatic restart is selectable |

|

|

|

| Frequency Limiter | High and low limits can be set for the output frequency between 0 to 200 Hz |

|

|

|

| Torque Boost | Torque boost level adjustable (manual torque boost) |

|

|

|

| Starting Torque | 100% at 3 Hz |

|

|

|

| Protection | |

|

|

|

| Overload | Detects overload to stop drive (150% for 1 minute) |

|

|

|

| Instantaneous Overcurrent | Detects overcurrent due to overload on the drive output side to protect drive. Protects drive in case of ground fault (when starting) and short circuit of output circuit. |

|

|

|

| Ground Fault Overvoltage | Detects DC link circuit overvoltage to stop drive |

|

|

|

| Undervoltage Overheating | Detects abnormal temperature of cooling fan to stop drive |

|

|

|

| Undervoltage Motor Protection | Electronic thermal overload detector |

|

|

|

| Alarm Output | Outputs a relay contact signal when any protective function is activated (SPDT contact, 250 VAC at 1A (30 VDC at 1A) |

|

|

|

| Options | |

|

|

|

| Standard | DIN-Rail mounting kit |

|

|

|

| Mounting Space | |

|

|

|

To purchase any Saftronics drives or information, contact us at:

Phone (815) 725-9696, Toll Free (866) 492-9888, Fax (815) 725-9393 or

E-mail info@joliettech.com